3M™ Dyneon™ Fluoroplastic PVDF 11010/0000

聚偏二氟乙烯 (PVDF)

3M Advanced Materials Division

3M™ Dyneon™ PVDF 11010/0000 is a copolymer of VF 2 and HFP (hexafluoropropylene). Recommended for flared tubing, it combines excellent chemical resistance, and dimensional stability with a moderate degree of flexibility. PVDF is ideal for multiple applications across a wide array of industries. Widely used in the chemical process industry, wire and cable industry, semiconductor industry, and oil and gas industry, PVDF is also gaining recognition in automotive, building, electronics, food processing, and pharmaceutical equipment and battery applications.

Features and Benefits

Good flexibility and mechanical strength in extruded tubing

Flareability of extruded tubing

Good chemical resistance to acids, bases, alcohols

材料特性:低透氣性、低煙度、低液體滲透性、高強(qiáng)度、高韌性、共聚物、抗溶劑、良好的柔韌性、耐候性良好、耐化學(xué)品良好、耐堿、耐酒精、耐酸、耐磨損良好、耐紫外光性能良好、阻燃、High Dimensional Stability

材料用途:電池、電氣/電子應(yīng)用領(lǐng)域、電線電纜應(yīng)用、非特定食品應(yīng)用、建筑材料、管件、汽車領(lǐng)域的應(yīng)用、石油/天然氣用品、天花板隔層電纜護(hù)套材料

加工方法:擠出

供貨地區(qū):北美洲、歐洲

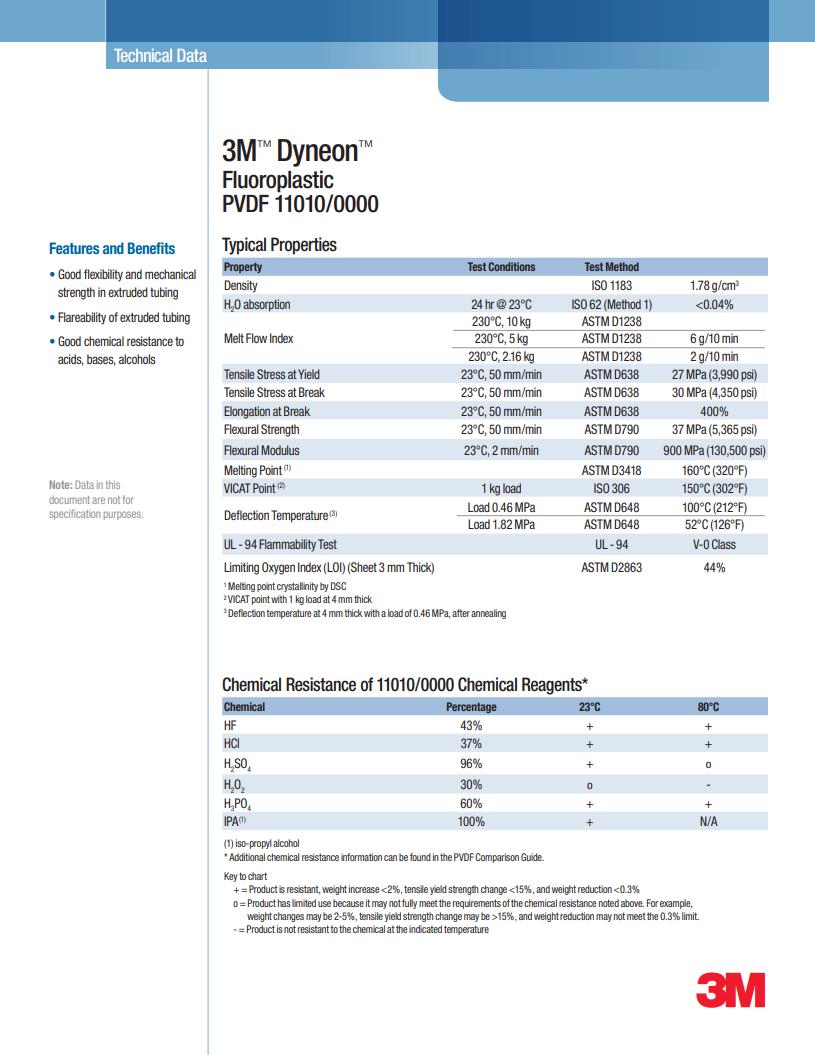

| 物理性能 | 額定值 | 單位制 | 測試方法 |

| 密度 | 1.78 | g/cm³ | ISO 1183 |

| 熔流率(熔體流動(dòng)速率) | ASTM D1238 | ||

| 230℃/2.16 kg | 2.0 | g/10 min | |

| 230℃/5.0 kg | 6.0 | g/10 min | |

| 吸水率(24 hr,23℃) | < 0.040 | % | ISO 62 |

| 機(jī)械性能 | 額定值 | 單位制 | 測試方法 |

| 抗張強(qiáng)度3 | ASTM D638 | ||

| 屈服,23℃ | 27.0 | MPa | |

| 斷裂,23℃ | 30.0 | MPa | |

| 伸長率1(斷裂,23℃) | 400 | % | ASTM D638 |

| 彎曲模量2(23℃) | 900 | MPa | ASTM D790 |

| 彎曲強(qiáng)度1(23℃) | 37.0 | MPa | ASTM D790 |

| 熱性能 | 額定值 | 單位制 | 測試方法 |

| 載荷下熱變形溫度 | ASTM D648 | ||

| 0.45 MPa,已退火,4.00 mm | 100 | ℃ | |

| 1.8 MPa,已退火,4.00 mm | 52.0 | ℃ | |

| 維卡軟化溫度 | 150 | ℃ | ISO 306/A |

| 熔融峰值溫度 | 160 | ℃ | ASTM D3418 |

| 可燃性 | 額定值 | 單位制 | 測試方法 |

| UL 阻燃等級 | V-0 | UL 94 | |

| 極限氧指數(shù)(3.00mm) | 44 | % | ASTM D2863 |

| 備注 150 mm/min 22.0 mm/min |

|||