Teflon® FEP CJ 99

聚全氟乙烯-丙烯樹(shù)脂

The Chemours Company

產(chǎn)品說(shuō)明:

For inventory control purposes product name may be followed by an X.

Products labeled FEP CJ 99 and FEP CJ 99 X are equivalent and all information in this document is applicable to both.

Typical Application

Wire and cable insulation, small tubing and injection molded parts.

Description

Teflon ™ FEP CJ 99 is a melt-processible copolymer of tetrafluoroethylene and hexafluoropropylene, without additives, that meets the requirements of ASTM D 2116 Type I.

Thanks to the unique combination of a Melt Flow Rate in the range of 9 g/10 min and MIT flexlife above 40 000 cycles, this resin offers both attractive processing speeds and high stress-rack resistance in addition to the excellent characteristics typical of Teflon ® fluoropolymer resins, such as non-ageing characteristics, chemical inertness, exceptional electrical properties, low flammability, heat resistance, toughness and flexibility, low coefficient of friction, non-stick characteristics, negligible moisture absorption and excellent weather resistance. The increased transparency of Teflon ® FEP CJ 99 will also allow better colourability.

Stress crack resistance is an important element in establishing end-use performance. Extensive testing of wire and cable constructions is required for definitive performance evaluation. Well-known and most comprehensive tests for stress rack resistance of wire and cable are mandrel wrap tests as described in the military specification MIL-W-22759 (aerospace) and ISO 6722/LV112 (automotive). Experience has shown that the MIT folding endurance or flex life test, based on ASTM D 2176, performed on a thin film of resin, gives a good correlation with stress crack resistance. Resins with a higher MIT flex life, perform better in the stress-crack resistance tests. Teflon ® FEP CJ 99 has a higher degree of stress crack resistance than most FEP resins with similar viscosity (MFR) and offers higher productivity than FEP resins with similar stress crack resistance (MIT). We recommend that for applications involving repeated thermal and flex cycling, specific tests on the final cable always should be undertaken. The MIT test results should be viewed as guide to comparative performance of the various grades of resin.

供貨地區(qū):北美洲、拉丁美洲、歐洲、亞太地區(qū)

黃卡號(hào)碼:E54681-533276

材料特性:低摩擦系數(shù)、低吸濕性、高 ESCR(抗應(yīng)力開(kāi)裂)、快的成型周期、良好的電氣性能、良好的柔韌性、良好的著色性、耐候性良好、耐化學(xué)品良好、耐熱高、韌性良好、食品接觸的合規(guī)性

材料用途:電線電纜應(yīng)用、絕緣材料

外觀形式:粒子

加工方法:吹塑成型、擠出、壓縮模塑、注射成型

物料性能:

| 物理性能 | 額定值 | 單位制 | 測(cè)試方法 |

| 密度/比重 | 2.13 | g/cm³ | ASTM D792,ISO 1183 |

| 熔流率(熔體流動(dòng)速率)(372°C/5.0 kg) | 9.0 | g/10 min | ASTM D2116,ISO 12086 |

| 吸水率(24 hr) | < 0.010 | % | ASTM D570 |

| 硬度 | 額定值 | 單位制 | 測(cè)試方法 |

| 肖氏硬度(邵氏 D) | 56 | ASTM D2240,ISO 868 | |

| 機(jī)械性能 | 額定值 | 單位制 | 測(cè)試方法 |

| 抗張強(qiáng)度(屈服,23°C) | 28.0 | MPa | ASTM D638,ISO 12086 |

| 伸長(zhǎng)率(斷裂,23°C) | 300 | % | ASTM D638,ISO 12086 |

| 沖擊性能 | 額定值 | 單位制 | 測(cè)試方法 |

| 懸壁梁缺口沖擊強(qiáng)度(23°C) | 無(wú)斷裂 | ASTM D256,ISO 180 | |

| 熱性能 | 額定值 | 單位制 | 測(cè)試方法 |

| 連續(xù)使用溫度1 | 205 | °C | |

| 熔融溫度 | 255 | °C | ASTM D4591,ASTM D3418 |

| 電氣性能 | 額定值 | 單位制 | 測(cè)試方法 |

| 介電強(qiáng)度 | |||

| 0.250 mm,方法A(短時(shí)間) | > 100 | kV/mm | ASTM D149 |

| 0.250 mm | > 100 | kV/mm | IEC 60243-1 |

| 介電常數(shù) | ASTM D150,IEC 60250 | ||

| 1 kHz | 2.03 | ||

| 1.00 GHz | 2.03 | ||

| 耗散因數(shù) | ASTM D150,IEC 60250 | ||

| 1 kHz | 5.0E-5 | ||

| 1.00 GHz | 8.0E-4 | ||

| 可燃性 | 額定值 | 單位制 | 測(cè)試方法 |

| UL 阻燃等級(jí)2 | V-0 | UL 94 | |

| 極限氧指數(shù) | > 95 | % | ASTM D2863,ISO 4589-2 |

| 補(bǔ)充信息 | 額定值 | 單位制 | 測(cè)試方法 |

| Critical Shear Rate(372°C) | 29.0 | sec^-1 | 內(nèi)部方法 |

| Guide DDR Range - for cable extrusion | 60.0 到 120 | ||

| MIT Folding Endurance - film(200.0 µm) | 4.0E+4 | Cycles | ASTM D2176 |

| 備注 1The continuous service temperature is based on accelerated heat-aging tests,and represents the temperature at which tensile strength and ultimate elongation retains 50% of the original values,after 20 000 h thermal aging When considering the use of Teflon ® FEP at elevated temperatures especially in combination with mechanical,electrical or chemical exposure,preliminary testing should be done to verify suitability. 2- These results are based on laboratory tests,under controlled conditions,and do not reflect performance under actual fire conditions. - Current rating is a typical theoretical value |

|||

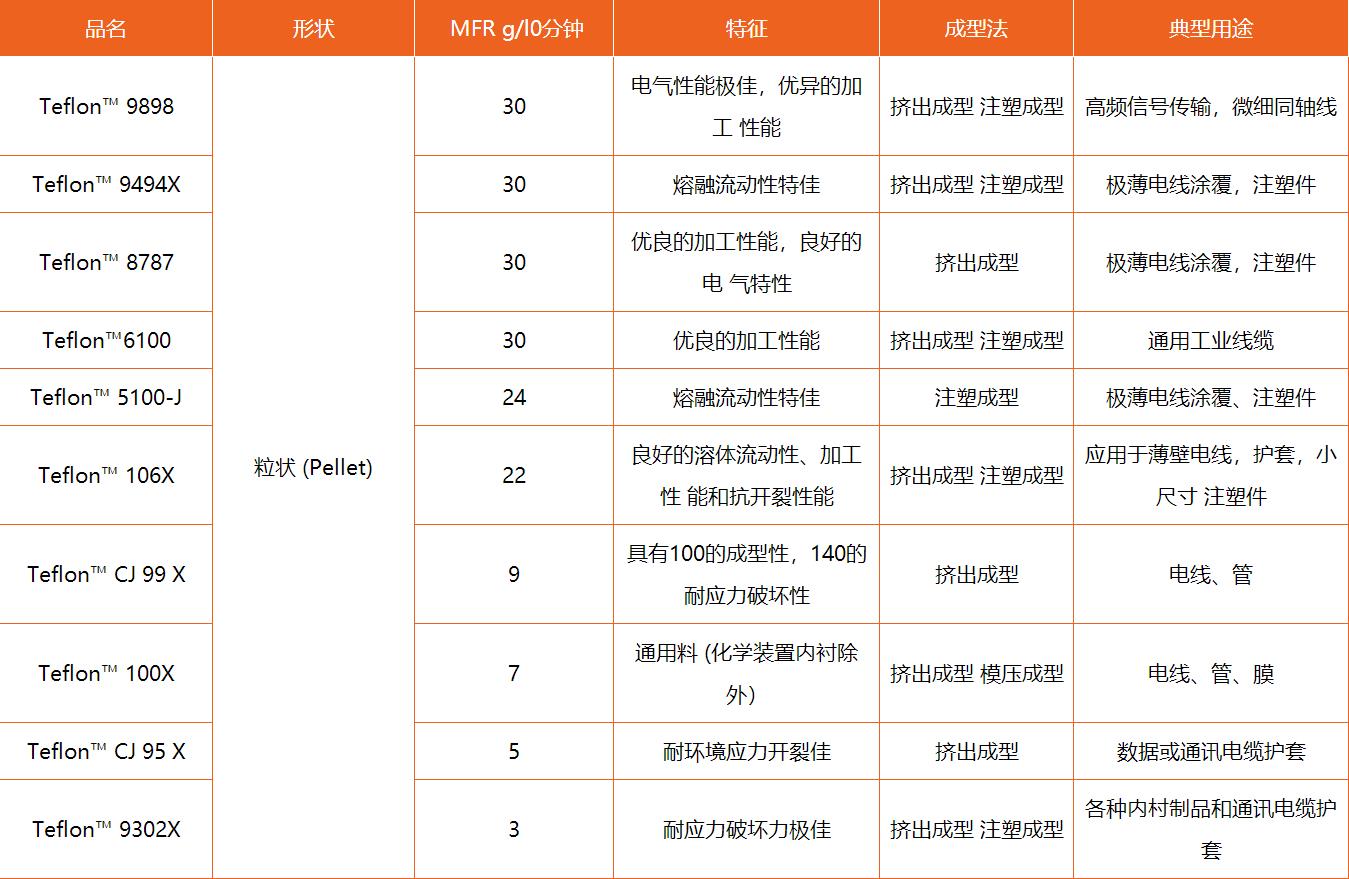

鐵氟龍™ FEP 聚全氟乙丙烯

連續(xù)最高使用溫度:200℃

極限氧指數(shù)(LOI):95%

﹡Teflon™FEP為四氟乙烯與六氟丙烯的共聚合產(chǎn)物,是一種可以熔融擠出成型的樹(shù)脂,因其優(yōu)越的加工性,使得Teflon™的用途增加,連續(xù)最高使用溫度為200°C。

﹡成型法與PFA相同,使用熔融擠出成型、傳遞成型、模壓成型等方法。

﹡Teflon™FEP為四氟乙烯與六氟丙烯的共聚合產(chǎn)物,是一種可以熔融擠出成型的樹(shù)脂,連續(xù)最高使用溫度為200°C。

﹡成型法與PFA相同,使用熔融擠出成型、傳遞成型、模壓成型等方法。

﹡與PTFE、PFA具有相似的耐化學(xué)藥品性、電氣特性。主要使用于電線絕緣/護(hù)套或管材擠出。Teflon™FEP為半透明顆粒料。

﹡FEP加工時(shí),所有與其熔體接觸的部件都必須采用耐腐蝕性材料如鎳基合金等。