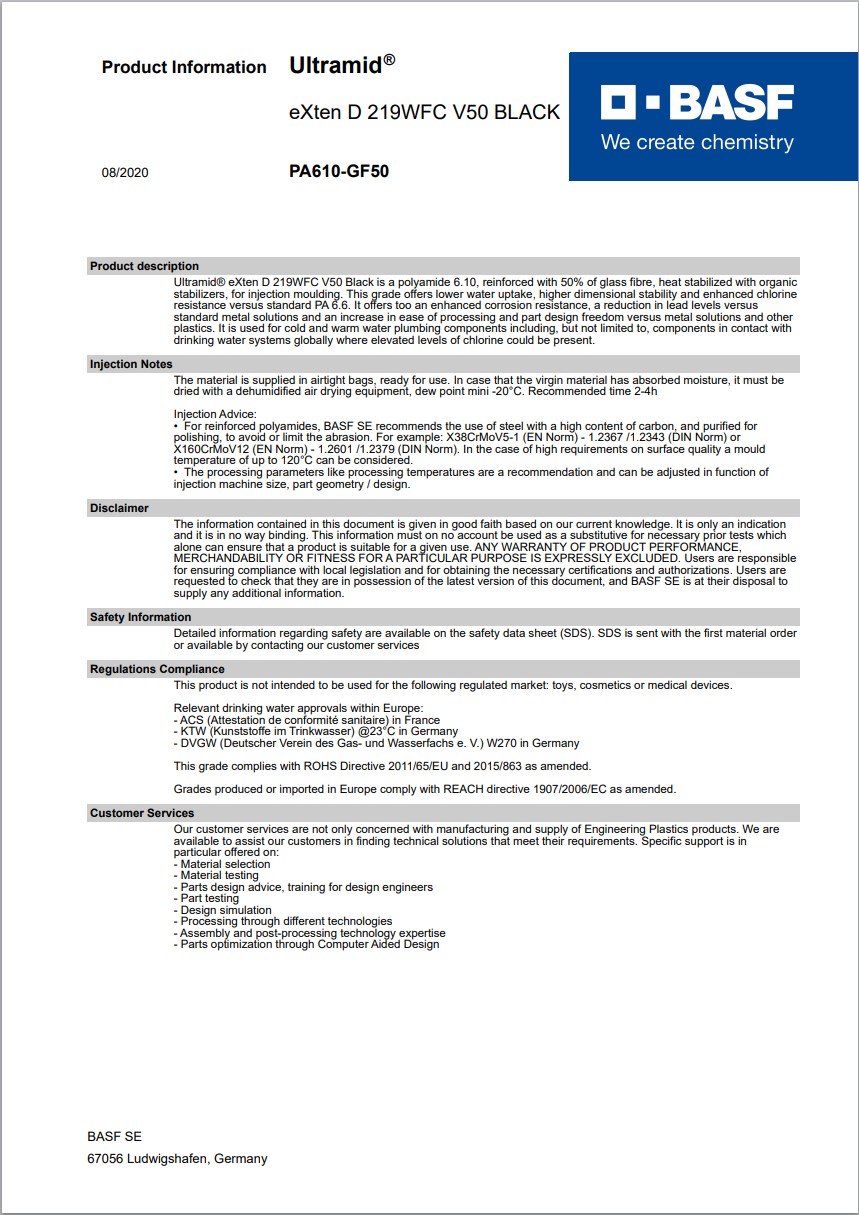

Ultramid® eXten D 219WFC V50 BLACK

聚酰胺 610(尼龍6/10)PA610-GF50

德國(guó)巴斯夫-BASF Corporation

產(chǎn)品說(shuō)明:

Ultramid® eXten D 219WFC V50 Black is a polyamide 6.10, reinforced with 50% of glass fibre, heat stabilized with organic stabilizers, for injection moulding. This grade offers lower water uptake, higher dimensional stability and enhanced chlorine resistance versus standard PA 6.6. It offers too an enhanced corrosion resistance, a reduction in lead levels versus standard metal solutions and an increase in ease of processing and part design freedom versus metal solutions and other plastics. It is used for cold and warm water plumbing components including, but not limited to, components in contact with drinking water systems globally where elevated levels of chlorine could be present.

增強(qiáng)材料:玻璃纖維50%增強(qiáng)

含添加劑:熱穩(wěn)定劑

材料特性:尺寸穩(wěn)定性良好,低(至無(wú))鉛含量,良好的加工性能,良好的抗腐蝕性,耐氯,吸水低或不吸水,Heat Stabilized - Organic

材料用途:管道部件,飲用水應(yīng)用

加工方法:黑色粒子注射成型

供貨地區(qū):北美洲,非洲和中東,拉丁美洲,亞太地區(qū)

中國(guó)代理:蘇州希普能工程塑料

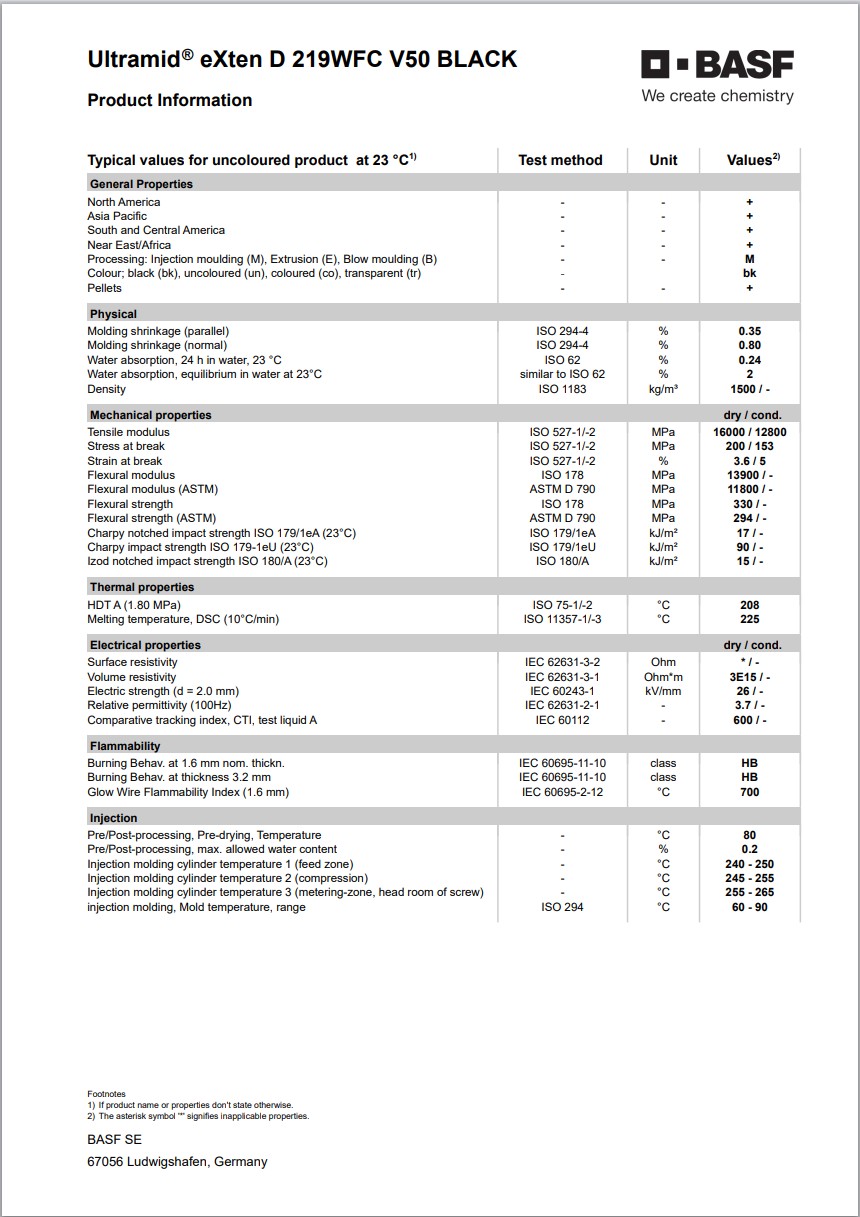

Ultramid® eXten D 219WFC V50 BLACK 巴斯夫中文加工參數(shù)表

| 物理性能 | 干燥 | 調(diào)節(jié)后的 | 單位制 | 測(cè)試方法 |

| 密度 | 1.50 | -- | g/cm³ | ISO 1183 |

| 收縮率 | ISO 294-4 | |||

| 垂直 | 0.80 | -- | % | |

| 流動(dòng) | 0.35 | -- | % | |

| 吸水率 | ISO 62 | |||

| 24 hr,23℃ | 0.24 | -- | % | |

| 飽和,23℃ | 2.0 | -- | % | |

| 機(jī)械性能 | 干燥 | 調(diào)節(jié)后的 | 單位制 | 測(cè)試方法 |

| 拉伸模量 | 16000 | 12800 | MPa | ISO 527-1 |

| 拉伸應(yīng)力(斷裂) | 200 | 153 | MPa | ISO 527-2 |

| 拉伸應(yīng)變(斷裂) | 3.6 | 5.0 | % | ISO 527-2 |

| 彎曲模量 | ||||

| -- | 11800 | -- | MPa | ASTM D790 |

| -- | 13900 | -- | MPa | ISO 178 |

| 彎曲強(qiáng)度 | ||||

| -- | 294 | -- | MPa | ASTM D790 |

| -- | 330 | -- | MPa | ISO 178 |

| 沖擊性能 | 干燥 | 調(diào)節(jié)后的 | 單位制 | 測(cè)試方法 |

| 簡(jiǎn)支梁缺口沖擊強(qiáng)度(23℃) | 17 | -- | kJ/m² | ISO 179/1eA |

| 簡(jiǎn)支梁無(wú)缺口沖擊強(qiáng)度(23℃) | 90 | -- | kJ/m² | ISO 179/1eU |

| 懸壁梁缺口沖擊強(qiáng)度(23℃) | 15 | -- | kJ/m² | ISO 180/A |

| 熱性能 | 干燥 | 調(diào)節(jié)后的 | 單位制 | 測(cè)試方法 |

| 載荷下熱變形溫度(1.8 MPa,未退火) | 208 | -- | ℃ | ISO 75-2/A |

| 熔融溫度 | 225 | -- | ℃ | ISO 11357-3 |

| 電氣性能 | 干燥 | 調(diào)節(jié)后的 | 單位制 | 測(cè)試方法 |

| 體積電阻率 | 3.0E+15 | -- | ohms·m | IEC 62631-3-1 |

| 介電強(qiáng)度(2.00mm) | 26 | -- | kV/mm | IEC 60243-1 |

| 相對(duì)電容率(100Hz) | 3.70 | -- | IEC 62631-2-1 | |

| 漏電起痕指數(shù)(解決方案A) | 600 | -- | V | IEC 60112 |

| 可燃性 | 干燥 | 調(diào)節(jié)后的 | 單位制 | 測(cè)試方法 |

| 可燃性等級(jí) | IEC 60695-11-10,-20 | |||

| 1.6 mm | HB | -- | ||

| 3.2 mm | HB | -- | ||

| 灼熱絲易燃指數(shù)(1.6mm) | 700 | -- | ℃ | IEC 60695-2-12 |

| 注射 | 干燥 | 單位制 | ||

| 干燥溫度 | 80 | ℃ | ||

| 建議的最大水分含量 | 0.20 | % | ||

| 料筒后部溫度 | 240 到 250 | ℃ | ||

| 料筒中部溫度 | 245 到 255 | ℃ | ||

| 料筒前部溫度 | 255 到 265 | ℃ | ||

| 模具溫度 | 60 到 90 | ℃ | ||

| 注射說(shuō)明 The material is supplied in airtight bags,ready for use. In case that the virgin material has absorbed moisture,it must be dried with a dehumidified air drying equipment,dew point mini -20℃. Recommended time 2-4h Injection Advice: For reinforced polyamides,BASF SE recommends the use of steel with a high content of carbon,and purified for polishing,to avoid or limit the abrasion.For example: X38CrMoV5-1 (EN Norm)-1.2367 /1.2343 (DIN Norm) or X160CrMoV12 (EN Norm)-1.2601/1.2379 (DIN Norm). In the case of high requirements on surface quality a mould temperature of up to 120℃ can be considered. The processing parameters like processing temperatures are a recommendation and can be adjusted in function of injection machine size,part geometry/design. |

||||