Teflon® PFA 9724

全氟烷氧基

The Chemours Company

產(chǎn)品說明:

For inventory control purposes product name may be followed by an X.

Products labeled PFA TE9724 and PFA TE9724 X are equivalent and all information in this document is applicable to both.

Typical Application

Teflon ™ PFA 9724 is an ideal resin for applications involving compounding and compression molding, as well as extruded tubing and other profiles for hose, electrical insulators, and sleeving; industrial film and products made from film; and injection or compression molded articles requiring superior electrical, chemical, and thermal properties. Teflon ™ PFA 9724 offers a slightly higher melt flow rate than Teflon ™ PFA TE9725, providing greater processing ease. .

Description

Teflon ™ PFA 9724 is a general-purpose fluoroplastic resin available as loosely compacted fluff. It is intended for use in special application processes in consultation with Chemours. Compared with other grades of Teflon ™ PFA, its most unique features are a relatively high flow rate and properties that make it suitable for a variety of processes and demanding end uses, especially compounding and compression molding. Table 1 shows the typical property data for Teflon ™ PFA 9724.

Teflon ® PFA TE9724 is used when traditional extrusion and molding processes are required for producing products with the superior properties of a fluoroplastic resin. Compared to other thermoplastics, the high melt strength and thermal stability of Teflon ® PFA TE9724 can be used to improve processing rates. Compared with other thermoplastics, Teflon ® PFA TE9724 provides a superior balance and level of end-use properties at high service temperatures. Teflon ® PFA TE9724 combines the processing ease of conventional thermoplastics with many properties similar to those of polytetrafluoroethylene.

Properly processed products made from neat Teflon ® PFA TE9724 resin provide the superior properties characteristic of fluoroplastic resins: chemical inertness, exceptional dielectric properties, heat resistance, toughness and flexibility, low coefficient of friction, non-stick characteristics, negligible moisture absorption, low flammability, performance at temperature extremes and excellent weather resistance.

In a flame situation, products of Teflon ® PFA TE9724 resist ignition and do not promote flame spread. When ignited by flame from other sources, their contribution of heat is very small and added at a slow rate with very little smoke.

Teflon ® PFA TE9724 meets the requirements of ASTM D3307, Type I

供貨地區(qū):北美洲、拉丁美洲、歐洲、亞太地區(qū)

材料特性:Excellent Weather Resistance、低摩擦系數(shù)、低吸濕性、低煙度、良好的電氣性能、良好的熔體強(qiáng)度、良好的柔韌性、流動性高、耐化學(xué)品良好、耐熱中等、熱穩(wěn)定良好、韌性良好

材料用途:薄膜、電氣/電子應(yīng)用領(lǐng)域、管道、管件、混料、型材

外觀形式:Fluff

加工方法:復(fù)合、擠出、樹脂傳遞成型、壓縮模塑、注射成型

物料性能:

| 物理性能 | 額定值 | 單位制 | 測試方法 |

| 密度/比重 | 2.14 | g/cm³ | ASTM D792 |

| 熔流率(熔體流動速率)(372℃/5.0 kg) | 12 | g/10 min | ASTM D3307,ISO 12086 |

| 吸水率(24 hr) | < 0.030 | % | ASTM D570 |

| 硬度 | 額定值 | 單位制 | 測試方法 |

| 肖氏硬度(邵氏 D) | 55 | ASTM D2240,ISO 868 | |

| 機(jī)械性能 | 額定值 | 單位制 | 測試方法 |

| 抗張強(qiáng)度(23℃) | 24.8 | MPa | ASTM D3307,ISO 12086 |

| 伸長率(斷裂,23℃) | 300 | % | ASTM D3307,ISO 12086 |

| 彎曲模量(23℃) | 586 | MPa | ASTM D790,ISO 178 |

| 熱性能 | 額定值 | 單位制 | 測試方法 |

| 熔融溫度 | 305 | ℃ | ASTM D4591 |

| 電氣性能 | 額定值 | 單位制 | 測試方法 |

| 體積電阻率 | 1.0E+18 | ohms·cm | ASTM D257,ISO 1325 |

| 介電強(qiáng)度 | |||

| 0.250 mm,方法A(短時(shí)間) | 80 | kV/mm | ASTM D149 |

| 0.250 mm | 80 | kV/mm | IEC 60243-1 |

| 介電常數(shù)(1 MHz) | 2.03 | ASTM D150,IEC 60250 | |

| 耗散因數(shù)(1 MHz) | < 2.0E-4 | ASTM D150,IEC 60250 | |

| 可燃性 | 額定值 | 單位制 | 測試方法 |

| UL 阻燃等級1 | V-0 | UL 94 | |

| 極限氧指數(shù) | > 95 | % | ASTM D2863,ISO 4589-2 |

| 補(bǔ)充信息 | 額定值 | 單位制 | 測試方法 |

| MIT Folding Endurance2(200.0 µm) | 1.5E+4 | Cycles | ASTM D2176 |

| 備注 1These results are based on laboratory tests under controlled conditions and do not reflect performance under actual fire conditions,current rating is a typical theoretical value. 2Depending on fabrication conditions |

|||

扎根于過去。放眼于未來。

Teflon™ PFA 是一種四氟乙烯-全氟烷氧基醚共聚物樹脂,可以提供顆粒狀和粉末狀兩種產(chǎn)品形態(tài)。這種氟聚合物樹脂可以改進(jìn)很多行業(yè)(包括化學(xué)加工、電子、半導(dǎo)體、制藥和生物技術(shù)領(lǐng)域)生產(chǎn)的產(chǎn)品。

Teflon™ PFA 樹脂的特性和優(yōu)勢

Teflon™ PFA 樹脂可以用傳統(tǒng)的熱熔擠出工藝或注塑、壓塑、滾塑成型、傳遞成型和吹塑工藝進(jìn)行加工。Teflon™ PFA 樹脂的熔體強(qiáng)度和熱穩(wěn)定性很高,有利于采用較大的模具孔和高溫涂布工藝,從而提高加工速度。

這種樹脂結(jié)合了傳統(tǒng)熱塑性樹脂的易加工優(yōu)勢和 Teflon™ PTFE(聚四氟乙烯)的出色性能,包括:

? 出色的耐化學(xué)腐蝕性

? 卓越的電氣性能

? 高達(dá) 260℃ (500°F) 的連續(xù)工作溫度

? 強(qiáng)大的耐高溫蠕變性能

? 出色的低溫韌性

? 出色的阻燃性

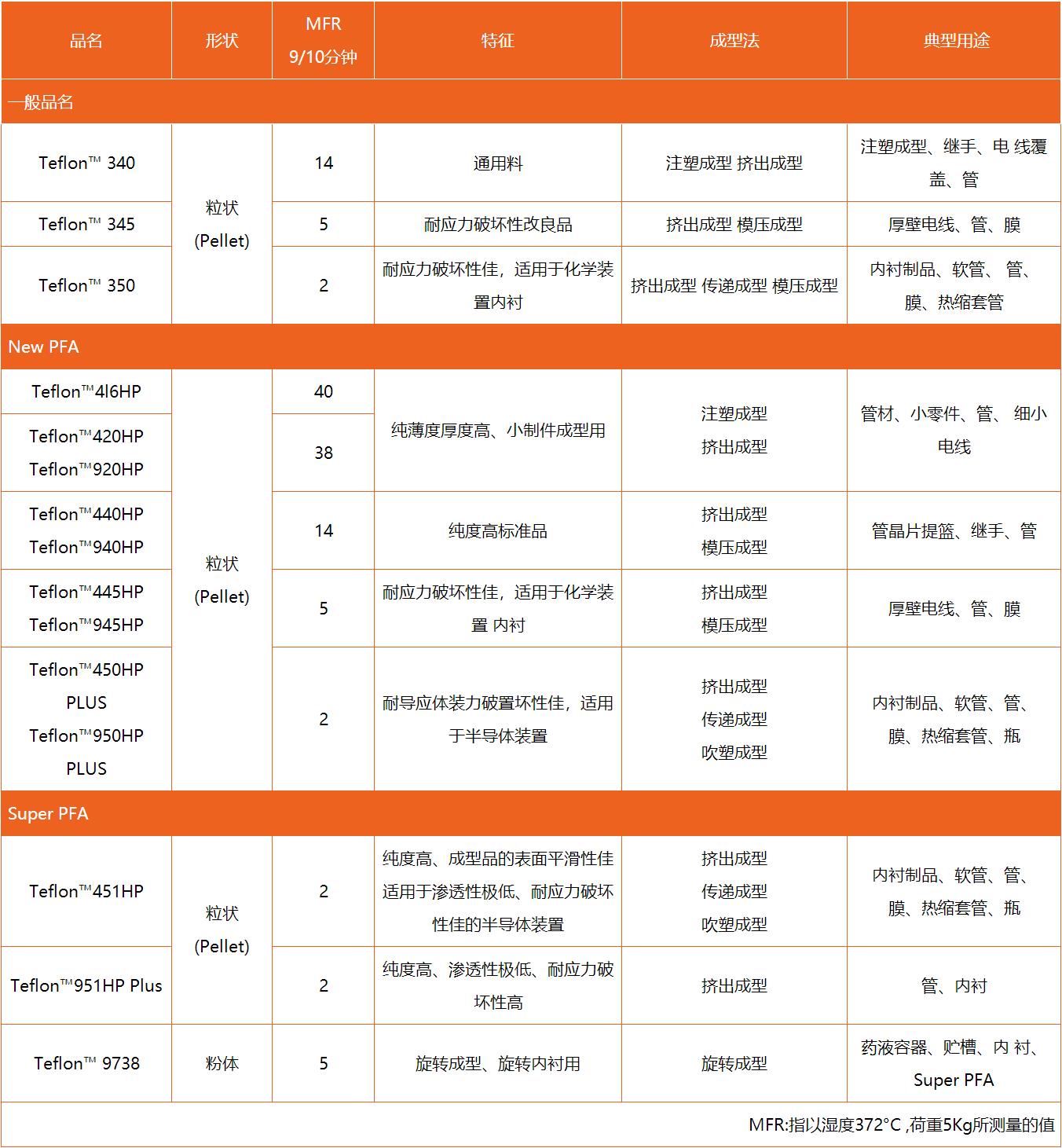

Teflon™ PFA 產(chǎn)品系列

Teflon™ PFA 產(chǎn)品系列包括各種熔體流動速率 (MFR) 的樹脂等級產(chǎn)品,這些產(chǎn)品適用于各種熱塑成型工藝,包括管和薄膜擠出成型、注塑、傳遞成型、壓塑成型和吹塑成型工藝。還可以提供用作涂層、薄膜或彌散材料的 PFA 產(chǎn)品。

Teflon™ PFA 300 系列

? Teflon™ PFA 300 系列樹脂是通用型 PFA 樹脂,適用于模壓或擠塑等熱塑性成型工藝

Teflon™ PFA 400HP 系列

? 完全氟化的 Teflon™ PFA 400HP 系列樹脂專為滿足化學(xué)流體處理行業(yè)對高純度和最小萃取量的要求而設(shè)計(jì)。

? Teflon™ PFA HP 氟聚合物樹脂制成的組件具有出色的耐化學(xué)腐蝕性和耐環(huán)境應(yīng)力開裂性。這種樹脂幾乎不受任何化學(xué)品和溶劑的影響。

Teflon™ PFA 900HP Plus 系列

? Teflon™ PFA 900HP Plus 氟聚合物樹脂具有與 Teflon™ PFA HP 等級產(chǎn)品一樣出色的耐化學(xué)腐蝕性、高純度和防離子污染性能,并且具有更長的抗撓曲壽命和更好的耐化學(xué)應(yīng)力開裂性能。此外,這種樹脂還賦予產(chǎn)品更高透明度和更好的表面光潔度,便于觀察在水處理系統(tǒng)中的雜質(zhì)并防止微生物在表面積聚。

? 這種樹脂能夠提供更穩(wěn)定可靠,無雜質(zhì)污染以及耐含氟表面活性劑等特性,滿足于半導(dǎo)體制造加工過程中日益嚴(yán)苛的要求。